NekMesh is designed to provide a pipeline approach to mesh generation. To do this, we break

up tasks into three different types. Each task is called a module and a chain of modules

specifies the pipeline.

The figure below depicts how these might be coupled together to form a pipeline:

On the command line, we would define this as:

Process modules can also have parameters passed to them, that can take arguments, or not.

To list all available modules use the -l command line argument:

and then to see the options for a particular module, use the -p command line argument:

-p option. Input modules should be preceded

by in:, processing modules by proc: and output modules by out:.

Input and output modules use file extension names to determine the correct module to use. Not every module is capable of reading high-order information, where it exists. The table below indicates support currently implemented.

| Format | Extension | High-order | Notes |

| Gmsh | msh | ✓ | Only reads nodes, elements and physical groups (which are mapped to composites). File format versions 2.x and 4.x currently supported. |

| Nektar | rea | ✓ | Reads elements, fluid boundary conditions. Most curve types are unsupported: high-order information must be defined in an accompanying .hsf file. |

| Nektar++ | xml | ✓ | Fully supported. |

| PLY | ply | ✗ | Reads only the ASCII format.. |

| Semtex | sem | ✓ | Reads elements and boundary

conditions. In order

to read high-order information,

run |

| Star-CCM+ | dat | ✗ | Star outputs plt file which currently needs to be coverted to ascii using Tecplot. Reads mesh only, only support for quads and triangles (2D) and hexes, prisms, tetrahedra (3D). |

| Star-CCM+ | ccm | ✗ | Reads start ccm format. Reads mesh only, only support for quads and triangles (2D) and hexes, prisms, tetrahedra (3D). Requires NEKTAR_USE_CCM option to be activated in cmake and then requires ccmio library to be compiled by user. |

| VTK | vtk | ✗ | Experimental support. Only ASCII triangular data is supported. |

Note that you can override the module used on the command line. For example, Semtex

session files rarely have extensions. So for a session called pipe-3d we can convert this using

the syntax

Typically, mesh generators allow physical surfaces and volumes to contain many element

types; for example a cube could be constructed from a mixture of hexes and prisms. In

Nektar++, a composite can only contain a single element type. Whilst the converter will

attempt to preserve the numbering of composites from the original mesh type, sometimes a

renumbering will occur when a domain contains many element types. For example, for a

domain with the tag 150 containing quadrilaterals and triangles, the Gmsh reader will print a

notification along the lines of:

The resulting file therefore has two composites of IDs 150 and 151 respectively, containing the

triangular and quadrilateral elements of the original mesh.

The following output formats are supported:

| Format | Extension | High-order | Notes |

| Gmsh | msh | ✓ | High-order hexes, quads, tetrahedra and triangles are supported up to arbitrary order. Prisms supported up to order 4, pyramids up to order 1. |

| Nektar++ | xml | ✓ | Most functionality supported. |

| VTK | vtk | ✗ | Experimental. Only ASCII triangular data is supported. |

Note that for both Gmsh and VTK, it is highly likely that you will need to experiment with

the source code in order to successfully generate meshes since robustness is not

guaranteed.

The default for xml is into binary data which has been converted into base64. If you wish to

see an ascii output you need to specify the output module option uncompress by executing:

Finally, both the Gmsh and Nektar++ output modules support an order parameter, which

allows you to generate a mesh of a uniform polynomial order. This is used in the same manner

as the above, so that the command

will generate an order 7 Gmsh mesh. In the rest of these subsections, we discuss the various

processing modules available within NekMesh.

Often one wants to visualise surfaces of a 3D mesh, or extract the values of variables on the

surface and visualise them. To support this, NekMesh can extract two-dimensional surfaces

which can be visualised using FieldConvert in order to extract the value of a 3D field on a

given surface.

As an example, we can extract composite surfaces 2 and 3-5 from a mesh using the extract

module:

If you also wish to have the boundaries of the extracted surface detected add the detectbnd

option

which will produce new composites for the extracted boundary.

To detect elements with negative Jacobian determinant, use the jac module:

To get a detailed list of elements which have negative Jacobians, one may use the list option:

and to extract the elements for the purposes of visualisation within the domain, use the

extract boolean parameter:

To turn off curvature associated with negative jacobians one can try to use the linearise

module:

This option will remove all high order curvature on all element types with singular jacobians.

Where high-order information is not available (e.g. when using meshes from imaging software),

various techniques can be used to apply a smoothing to the high-order element. In NekMesh we

use spherigons, a kind of patch used in the computer graphics community used for efficiently

smoothing polygon surfaces.

Spherigons work through the use of surface normals, where in this sense ‘surface’ refers to the

underlying geometry. If we have either the exact or approximate surface normal at each given

vertex, spherigon patches approximate the edges connecting two vertices by arcs of a circle. In

NekMesh we can either approximate the surface normals from the linear elements which

connect to each vertex (this is done by default), or supply a file which gives the surface

normals.

To apply spherigon patches on two connected surfaces 11 and 12 use the following command:

If the two surfaces "11" and "12" are not connected, or connect at a sharp edge which is C0 continuous but not C1 smooth, use two separate instances of the spherigon module.

This is to avoid the approximated surface normals being incorrect at the edge.

If you have a high-resolution mesh of the surfaces 11 and 12 in ply format it can be used to

improve the normal definition of the spherigons. Run:

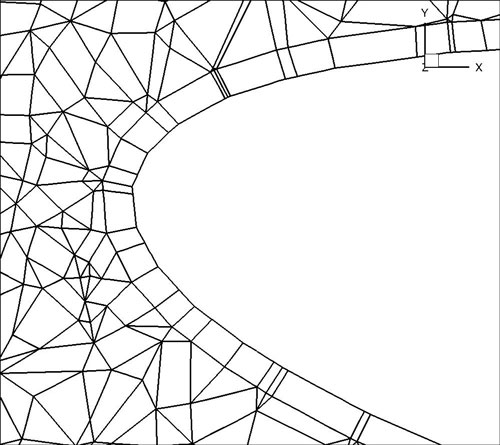

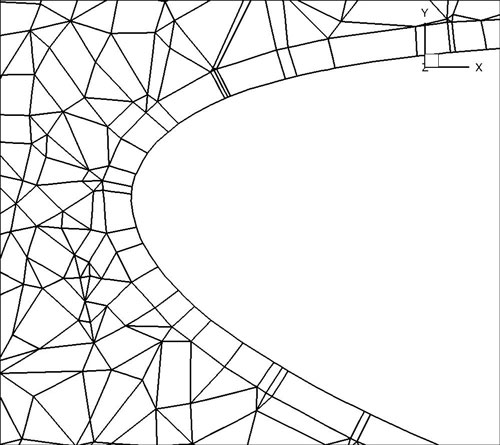

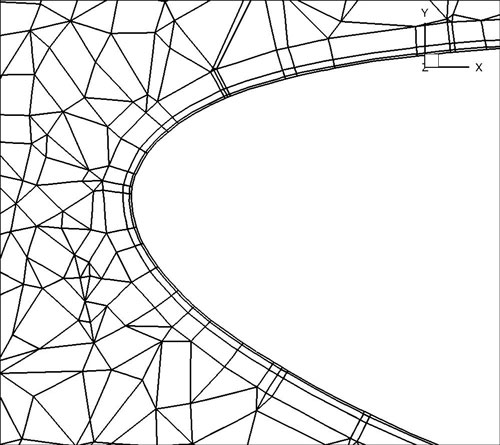

This can be useful, for example, when meshing the Leading edge of an airfoil. Starting from a linear mesh (left figure) the spherigon patches curve the surface elements producing leading edge closer to the underlying geometry:

When using periodic boundary conditions, the order of the elements within the boundary composite determines which element edges are periodic with the corresponding boundary composite.

To facilitate this alignment, NekMesh has a periodic alignment module which attempts to

identify pairs of mutually periodic edges. Given two surfaces surf1 and surf2, which for

example correspond to the physical surface IDs specified in Gmsh, and an axis which defines

the periodicity direction, the following command attempts to reorder the composites:

Here the surfaces with IDs 11 and 12 will be aligned normal to the y-axis and the surfaces 13 and 14 will be aligned normal to the z-axis.

Note that this command cannot perform magic – it assumes that any given edge or face lying on the surface is periodic with another face on the opposing surface, that there are the same number of elements on both surfaces, and the corresponding edge or face is the same size and shape but translated along the appropriate axis.

When using periodic boundary conditions that are rotationally aligned the following rotational options should be applied:

where rot specifies the rotation angle in radians from surf1 to surf2 about the axis specified

by dir (i.e. the “x” axis in this example). An optional tolerance tol can also be specified

which is the tolerance within which the rotation is assumed to be exact. The default tolerance

is 1e-8.

In 3D, where prismatic or tetrahedral elements are connected to one or both of the surfaces,

additional logic is needed to guarantee connectivity in the XML file. In this case we append

the orient parameter:

orient is that it throws away all high-order

information and works only on the linear element. This can be gotten around if you are just

doing e.g. spherigon patches by running this peralign module before the spherigon

module.

Often it is the case that one can generate a coarse boundary layer grid of a mesh. NekMesh has

a method for splitting prismatic and hexahedral elements into finer elements based on the

work presented in [31] and [32]. You must have a prismatic mesh that is O-type

– that is, you can modify the boundary layer without modifying the rest of the

mesh.

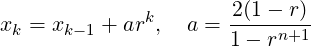

Given n layers, and a ratio r which defines the relative heights of elements in different layers, the method works by defining a geometric progression of points

in the standard segment [-1,1]. These are then projected into the coarse elements to construct a sequence of increasingly refined elements, as depicted in figure 4.4.

To split a prism boundary layer on surface 11 into 3 layers with a growth rate of 2 and 7 integration points per element use the following command:

r=sin(x). In this case the function should be sufficiently smooth to

prevent the elements self-intersecting.

Generating accurate high-order curved geometries in Gmsh is quite challenging. This

module processes an existing linear cylindrical mesh, with axis aligned with the

z-coordinate axis, to generate accurate high-order curvature information along the

edges.

The module parameters are:

surf: Surface on which to apply curvature. This should be the outer surface of the

cylinder.

r: Radius of the cylinder.

N: Number of high-order points along each element edge.

The ability to remove all the high-order information in a mesh can be useful at times when mesh generation is tricky or impossible in the presence of curvature

To do this in NekMesh use the command:

The output will contain only the linear mesh information, all curved information is removed. Alternatively

attempts to remove curvature from elements only where necessary. This is a simple algorithm

that removes curvature from invalid elements and repeats until all elements are valid. Either

all or invalid must be specified.

all: remove curvature from all elements.

invalid: remove curvature from invalid elements.

prismonly: consider only prisms when removing curvature. This is useful in the

presence of a prismatic boundary layer.

When the mesh is three-dimensional and comprised of a prismatic boundary layer with tetrahedra in the interior of the domain, this module extracts the prismatic elements only, and constructs a boundary region for the interface between the tetrahedra and prisms. This is useful in, for example, the study of aortic flows, where the prismatic boundary layer can be extracted and refined to study unsteady advection-diffusion problems on a more refined grid inside the boundary layer.

To use this module you therefore use the command:

There are no configuration options for this module, as it is highly specific to a certain class of meshes.

Some mesh formats lack the ability to identify boundaries of the domain they discretise.

NekMesh has a rudimentary boundary identification routine for conformal meshes, which will

create a composite of edges (2D) or faces (3D) which are connected to precisely one element.

This can be done using the detect module:

This module imposes curvature on a surface given a scalar function z = f(x,y). For example, if on surface 1 we wish to apply a surface defined by a Gaussian z = exp[-(x2 + y2)] using 7 quadrature points in each direction, we may issue the command

It is quite possible that a mesh contains some sort of hanging entity or element connectivity error. The check link module is a fast check that, a) elements are correctly connected and b) the boundary entities (composites) match the interior domain:

This module should be added to the module chain if the user suspects there may be a mesh issue. The module will print a warning if there is a connectivity error.

This module allows a 2D mesh, quads, triangles or both, to be extruded in the z direction to make a simple 3D mesh made of prisms and hexahedra. It is also capable of extruding the high-order curvature within the 2D mesh. The module requires two parameters:

length which determines how long the z extrusion will be and layers, the number of elements in the z direction.

This module can correct invalid and improve the quality of elements in high-order meshes by applying curvilinear deformation to the interiors of domains. It achieves this by solving a solid mechanics system which, using variational calculus has been cast is a non-linear energy optimsation problem. It is basis of the work in [43].

It works by considering the boundary (curved) mesh entities to be fixed and moving the interior nodes to a lower energy configuration. This new configuration in most scenarios is a higher quality mesh. The energy is evaluated depending on which functional is chosen. We find hyperleastic to be the most reliable but it can also model the mesh and a linearelastic solid as well as functionals based on the Winslow equation and the distortion method proposed by Roca et al. [14].

There are a large number of options which can be viewed using the help function but the basic usage is:

where type can be hyperelastic, linearelastic, winslow or roca.

This module can take any linear mesh, providing that it is a close representation of the CAD and project the boundary of the mesh onto the CAD. This will curve the surface of the mesh. The method has a number of failsafes ensuring that even bad CAD or poor linear meshes should be able to be curved to some degree. If the method encounters an issue, such as the linear mesh being a large distance from the CAD, it will simply leave that element straight sided. A well made CAD model and accurate linear mesh should be curved with little issue.

The module needs to be informed of the CAD file to project the mesh to and the order at which to curve the surface: